Meating customer needs

Andersons’

self-serve beef bin draws customers

from near, far

By Ben Sonnek

STAFF WRITER

BELGRADE — For years, the Anderson family — Dale and Deb Anderson and their son and daughter-in-law, Justin and Mandy Anderson — have been ready to try new things with Colfax Farms. One of their latest projects, a self-serve beef bin, has been bringing homegrown meat to a stand by the side of the highway.

“I think people are having a greater appreciation for local meat and products in general,” Mandy said. “I’ve told many people, ‘You don’t have to buy anything, just stop and look.’”

The farm has been in the Anderson family for over 150 years, making Justin and Mandy the sixth generation on the farm — and their children the seventh. It started as a dairy. When Dale was growing up, they raised chickens and pigs, and sheep were added to the farm for a time. Now, the farm raises beef cattle, which work the best for the land’s pastures and fencing; Justin feeds out steers, and Dale custom feeds out about 4,400 head of pigs on his land. Additionally, the Andersons were recognized as the Kandiyohi County Soil and Water Conservation District’s Outstanding Conservationist of 2025.

When the Andersons were looking for ways to sell their beef, a crop insurance adjustor put forward the roadside stand idea, a concept that fit well with the farm’s location on Highway 71, south of Belgrade. The Andersons also liked it because it was less labor-intensive and more regular than farmers markets, and it did not require them to staff their own storefront.

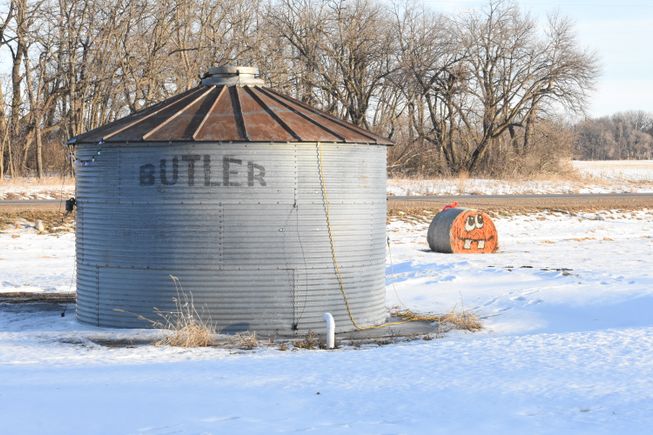

After a couple of years of tossing the idea around, the Andersons put down a concrete pad by the side of the road, ran electricity to the site, and, July 13, 2025, moved one of their farm’s bins down the driveway to set it up on the pad. With the addition of the meat freezer, decorations and a sign-in book, the beef bin opened Aug. 2, 2025.

“One day last summer, it was like, ‘We’re going to get this done,’” Deb said. “We were hoping for the Fourth of July, but that didn’t happen.”

To stock the beef bin, the Andersons butchered two beef cows, which supplied the bin not only with steaks, roasts, hamburger, hamburger patties, stew meat, fajita meat and rendered tallow but also harder-to-find meats like beef heart, kidney and liver. During the summer, the family needed to resupply the bin nearly every day, sometimes multiple times per day.

“It was interesting how fast some of the organ meats disappeared,” Dale said. “There are people out there looking for that odd stuff, too.”

The beef bin also sells honey from the Andersons’ bees as well as beeswax and beef tallow soap; in the fall, they sold vegetables, sweet corn and pumpkins around the bin as well.

The pumpkins in particular encouraged more people to stop and check out the site.

The Andersons were expecting to get mostly local people in their beef bin’s sign-in book. While there are plenty of visitors’ notes from people who say they drove by daily and finally decided to stop, there are also notes from residents of Moorhead, Fargo, North Dakota, Iowa, Canada and other locations along Highway 71.

“I’m still shocked at how many out-of-town people stopped,” Mandy said.

To reduce the risk of theft, the Andersons keep a limited amount of product in the bin, and a camera is installed out there for security. However, it is rare for any meat to go unaccounted for.

“Everyone told us we were crazy,” Justin said. “There definitely is a risk. Just last week, there was some meat missing and no money. … Maybe they needed it more than we did, (but) we don’t want that to keep happening.”

The beef bin has been an opportunity for Colfax Farms to share its beef-raising practices. The cattle are grain finished, hand-fed daily and raised in pasture; for planting, the Andersons have been adding more cover crops on the row crop acres, and in the fall, they will graze cover crops and crop residue. The family is currently building a new steer barn, and when it is done, it will have a feed-mixing robot that can also feed the cattle when needed.

The results speak for themselves — through the farm’s customers.

“If you flip through the (sign-in) book, a lot of people comment on how good it (the beef) is,” Deb said.

While there is not a beef product the Andersons will not recommend, they are happy their beef bin has not only satisfied customers but has also gotten people thinking about where their meat comes from.

“We’re getting people to talk about the beef industry and meat in general,” Dale said. “(People) are stopping for local beef along the road, knowing … it’s a local-raised product. People are looking for that.”

self-serve beef bin draws customers

from near, far

By Ben Sonnek

STAFF WRITER

BELGRADE — For years, the Anderson family — Dale and Deb Anderson and their son and daughter-in-law, Justin and Mandy Anderson — have been ready to try new things with Colfax Farms. One of their latest projects, a self-serve beef bin, has been bringing homegrown meat to a stand by the side of the highway.

“I think people are having a greater appreciation for local meat and products in general,” Mandy said. “I’ve told many people, ‘You don’t have to buy anything, just stop and look.’”

The farm has been in the Anderson family for over 150 years, making Justin and Mandy the sixth generation on the farm — and their children the seventh. It started as a dairy. When Dale was growing up, they raised chickens and pigs, and sheep were added to the farm for a time. Now, the farm raises beef cattle, which work the best for the land’s pastures and fencing; Justin feeds out steers, and Dale custom feeds out about 4,400 head of pigs on his land. Additionally, the Andersons were recognized as the Kandiyohi County Soil and Water Conservation District’s Outstanding Conservationist of 2025.

When the Andersons were looking for ways to sell their beef, a crop insurance adjustor put forward the roadside stand idea, a concept that fit well with the farm’s location on Highway 71, south of Belgrade. The Andersons also liked it because it was less labor-intensive and more regular than farmers markets, and it did not require them to staff their own storefront.

After a couple of years of tossing the idea around, the Andersons put down a concrete pad by the side of the road, ran electricity to the site, and, July 13, 2025, moved one of their farm’s bins down the driveway to set it up on the pad. With the addition of the meat freezer, decorations and a sign-in book, the beef bin opened Aug. 2, 2025.

“One day last summer, it was like, ‘We’re going to get this done,’” Deb said. “We were hoping for the Fourth of July, but that didn’t happen.”

To stock the beef bin, the Andersons butchered two beef cows, which supplied the bin not only with steaks, roasts, hamburger, hamburger patties, stew meat, fajita meat and rendered tallow but also harder-to-find meats like beef heart, kidney and liver. During the summer, the family needed to resupply the bin nearly every day, sometimes multiple times per day.

“It was interesting how fast some of the organ meats disappeared,” Dale said. “There are people out there looking for that odd stuff, too.”

The beef bin also sells honey from the Andersons’ bees as well as beeswax and beef tallow soap; in the fall, they sold vegetables, sweet corn and pumpkins around the bin as well.

The pumpkins in particular encouraged more people to stop and check out the site.

The Andersons were expecting to get mostly local people in their beef bin’s sign-in book. While there are plenty of visitors’ notes from people who say they drove by daily and finally decided to stop, there are also notes from residents of Moorhead, Fargo, North Dakota, Iowa, Canada and other locations along Highway 71.

“I’m still shocked at how many out-of-town people stopped,” Mandy said.

To reduce the risk of theft, the Andersons keep a limited amount of product in the bin, and a camera is installed out there for security. However, it is rare for any meat to go unaccounted for.

“Everyone told us we were crazy,” Justin said. “There definitely is a risk. Just last week, there was some meat missing and no money. … Maybe they needed it more than we did, (but) we don’t want that to keep happening.”

The beef bin has been an opportunity for Colfax Farms to share its beef-raising practices. The cattle are grain finished, hand-fed daily and raised in pasture; for planting, the Andersons have been adding more cover crops on the row crop acres, and in the fall, they will graze cover crops and crop residue. The family is currently building a new steer barn, and when it is done, it will have a feed-mixing robot that can also feed the cattle when needed.

The results speak for themselves — through the farm’s customers.

“If you flip through the (sign-in) book, a lot of people comment on how good it (the beef) is,” Deb said.

While there is not a beef product the Andersons will not recommend, they are happy their beef bin has not only satisfied customers but has also gotten people thinking about where their meat comes from.

“We’re getting people to talk about the beef industry and meat in general,” Dale said. “(People) are stopping for local beef along the road, knowing … it’s a local-raised product. People are looking for that.”